lightning protection

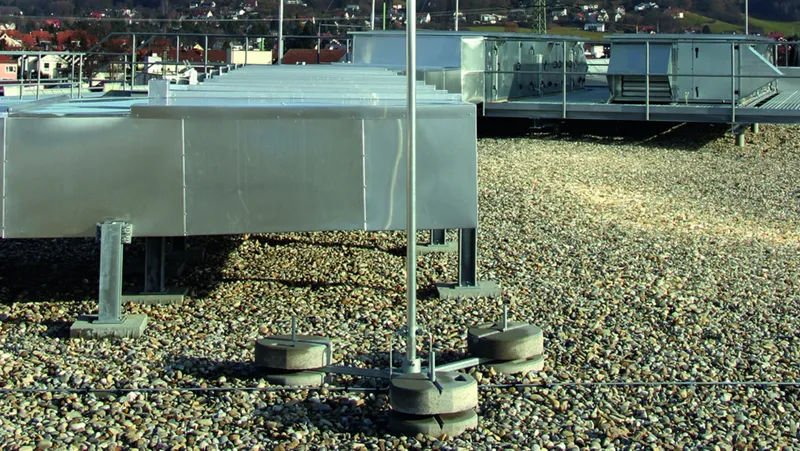

AirTerminationRods & Accessories

Ensure complete protection for your elevated roof-mounted structures and buildings with our advanced range of air-termination rods, precision-engineered tips, and telescopic lightning protection masts. Our high-performance accessories are designed to deliver maximum safety, reliability, and ease of installation in even the most demanding environments

Air-termination Rods, Accessories

Air – termination rods , air -termination tips , tele-scopic lightning protection masts and accessories for protecting elevated roof-mounted structure or buildings.

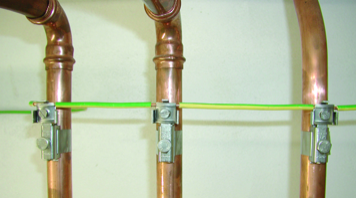

Down Conductor& Conductor Holders

Designed for all roof types and facades—including flat roofs, metal surfaces, ridge and hip tiles—our conductor systems offer secure and adaptable solutions for both round and flat conductors. Down conductors, a critical component in safely directing lightning energy to ground, are given special attention to ensure complete system reliability. Every installation detail is carefully considered, delivering robust protection, long-term durability, and full compliance with international lightning protection standards

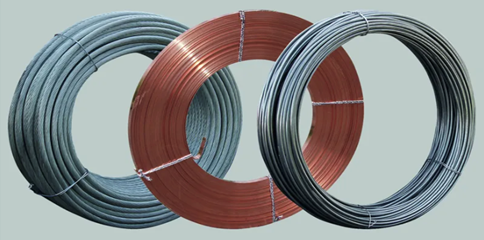

Conductors, Round Wires, Strips, Ca-bles

Round wires, strips and cables, different ma-terials and diameters, for lightning protection and earth-termination systems and for equipotential bonding

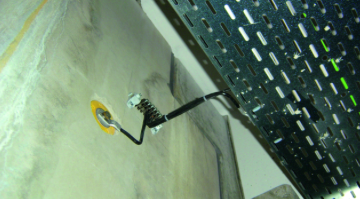

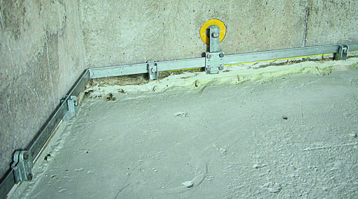

Flat Roof – Roof Conductor Holders, Bridging Braids

Roof conductor holders, expansion pieces and bridging components (cables, strips, lugs) for flat roofs.

HVI Conductors

High-voltage-resistance insulated HVI down conductors for maintaining the separation distance from conductive parts.

Metal Roof / Corrugated Sheet Roof-ing – Roof Conductor Holders

Roof conductor holders for installing an air-termination system on a metal or corrugated sheet/trapezoidal roof.

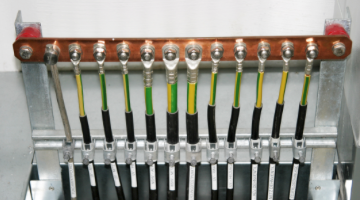

Equipotential Bonding

Equipotential bonding is a critical element in electrical safety and lightning protection systems. Its main purpose is to eliminate dangerous potential differences between conductive parts during fault conditions or lightning strikes, thus protecting both people and equipment.

Equipotential bonding bars – industry

Equipotential bonding busbars for the protec-tive and functional equipotential bonding ac-cording to IEC 60364-4-41/60364-5-54 (DIN VDE 0100-410/540) and lightning equipoten-tial bonding according to IEC/EN 62305-3.Also for use in potentially explosive atmospheres (secured against self-loosening of screws).

With spring washer

Insulator UP (duroplastic, red) with M10 thread

UV-stabilised and halogen-free

Equipotential Bonding Busbars R15 with Terminal Block System / Kit

Equipotential bonding busbars for protective and functional equipotential bonding accord-ing to IEC 60364-4-41/60364-5-54 and light-ning equipotential bonding according to

IEC/EN 62305-3

Tested according to DIN VDE 0609

15 modules

Grey plastic bar frames and cover (halo-gen-free)

Sealable/labelable cover

Terminal block, St/gal Zn

Equipotential Bonding Busbar with Miniature Terminal Block System

Equipotential bonding busbars for protective and functional equipotential bonding accord-ing to IEC 60364-4-41/60364-5-54 in small in-stallations.

Tested according to DIN EN 60999-2

Terminal block, St/gal Zn

Flat Strip / Round Conductor Holders with Thrust Piece

For wall mounting.

Thrust piece with M8 screw for installing flat strips up to 11 mm and round conductors 6-10 mm.

Tailored Materials for Every Project Nature

The selection of materials used in lightning protection systems is critically important to ensure system effectiveness and long-term reliability. Choosing the wrong materials can lead to serious technical failures and safety risks.

Copper

Air terminals ,tape , round conductor

& all needed accessories

Aluminum

Air terminals ,tape , round conductor

& all needed accessories

Galvanized steel

terminals ,tape , round conductor

& all needed accessories

stainless steel

Air terminals ,tape , round conductor

& all needed accessories

Here’s why proper material selection matters:

1. Electrochemical Compatibility & Corrosion Prevention

• Using dissimilar metals (e.g., copper with aluminum or galvanized steel) can lead to galvanic corrosion, especially at connection points.

• This corrosion weakens the system over time and can result in loss of continuity and system failure.

2. Electrical Conductivity

• Materials must have low electrical resistance to effectively conduct the high currents from lightning strikes.

• Substandard materials may not safely carry lightning energy, increasing the risk of fire, equipment damage, or injury.

3. Durability and Environmental Resistance

• Lightning protection components are often installed outdoors and must withstand harsh weather conditions over years.

• Inappropriate materials may rust, crack, or degrade, compromising the system’s functionality.

4. Compliance with International Standards

• Standards like IEC 62305 clearly define acceptable materials and specifications.

• Non-compliance can lead to rejection of the installation by consultants or inspectors and could void warranties or insurance.

5. System Compatibility

• All components—air terminals, down conductors, bonding systems, and earth terminations—must be made from compatible materials to ensure proper integration and performance.

• Incompatible materials may result in weak points or ineffective connections.

Certified Materials, Certified Protection

To ensure the quality and reliability of materials used in lightning protection systems, several critical tests must be conducted in accordance with recognized international standards. These tests verify the material’s electrical, mechanical, and environmental performance, ensuring long-term system safety and compliance.

Tested for Safety – Because Lightning Doesn’t Forgive Mistakes

1. Electrical Conductivity Test

• Purpose: Ensure low resistance for efficient lightning current conduction.

• Standards:

• IEC 62561-2 (for conductors and earth electrodes)

• IEC 60068-2-1/2 (general testing methods)

• ASTM B193 (measuring electrical resistivity of metals)

2. Corrosion Resistance Test

• Purpose: Evaluate material durability under environmental exposure (e.g., moisture, salt).

• Common Test: Salt Spray Test

• Standards:

• IEC 62561-1, 62561-2, 62561-3

• ISO 9227 (Neutral Salt Spray – NSS)

3. Mechanical Strength Test

• Purpose: Confirm the material’s ability to withstand physical loads (wind, installation stresses).

• Standards:

• IEC 62561-1 (Air Termination Components)

• IEC 60068-2-75 (Impact tests)

4. High Current Withstand Test

• Purpose: Simulate direct lightning strike conditions to ensure the material survives without failure.

• Standards:

• IEC 62561-1 / 62561-2

• Test pulse: 30/100 µs waveform up to 100 kA

• IEC 62305-3 (overall performance reference)

5. Contact Resistance Test

• Purpose: Ensure high-quality, low-resistance bonding at joints and terminals.

• Standards:

• IEC 62561-1 / IEC 62561-2

• IEEE Std 837 (for permanent grounding connections)

6. Material Composition / Purity Test

• Purpose: Verify the purity and chemical makeup of materials, especially copper and aluminum.

• Standards:

• ASTM B187 / B170 (for copper wires and bars)

• ASTM E415 (optical emission analysis for chemical composition)

7. Environmental Aging Test

• Purpose: Assess long-term resistance to UV, humidity, and temperature cycling.

• Standards:

• IEC 60068-2-5 (UV testing)

• IEC 60068-2-30 (humidity cycling)