Earthing Solutions

Vertical Rod – Efficient and Reliable GroundingSystems

Vertical rod grounding systems are among the most commonly used types of earthing, especially in areas with low to medium soil resistivity. These systems offer a practical and cost-effective solution for achieving the required earth resistance. The rods can be manufactured from various materials—such as copper-bonded steel, galvanized steel, or stainless steel—selected based on the soil’s chemical composition and environmental conditions. Proper selection ensures system durability, corrosion resistance, and long-term electrical performance.

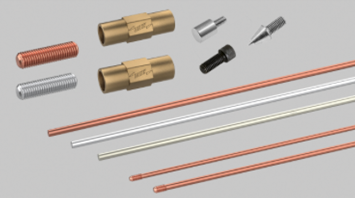

Copper-bonded earth rods

The rods are manufactured from low carbon, high tensile steel with a 99.9% pure electrolytic copper thickness of 250 microns. Thread rolling after plating preserves the copper thickness en-suring corrosion resistance across the threads. Threads comply with ANSI/ASME B1.1-2003.

Extensible earth rods are coupled using thread-ed, easy to use brass couplings. Connections can be made by using bolted clamps or exother-mic welding process.

By specifying UL listed earth rods you ensure full compliance to the standard UL 467. Only products bearing the UL listing mark are cov-ered by UL’s listing and follow-up service.

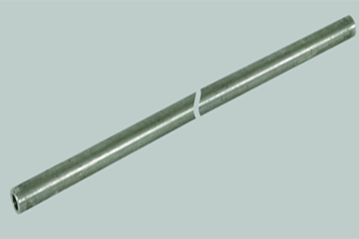

Earth Rods

For setting up earthing systems for down con-

ductors or transformer stations.Features:

No thickening of the cross-section at the cou-pling joint

Self-locking coupling

Corrosion resistance

Easier storage and transport

Universal use according to local soil condi-tions

Constant resistance values

Easily driven in with a vibration hammer

Exothermic Welding

The exothermic welding process, also known as thermite welding and alumina-thermic welding is a simple, self-contained method of forming hight quality electrical connections of various metals such as coper to copper, copper to steel and steel to steel.

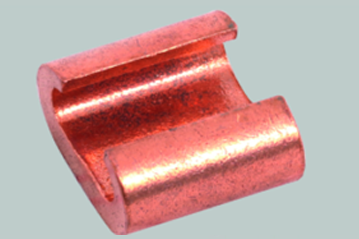

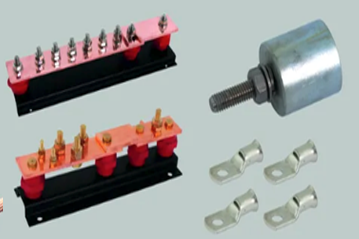

Equipotential Bonding

Products for installing an earth-termination sys-tem and for establishing equipotential boding

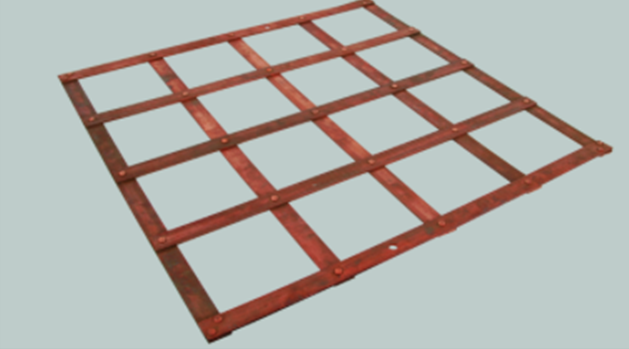

Mesh Grounding: The Practical Choice for High-Resistivity Soils

This solution is effective because a mesh grounding system increases the contact area with the soil, reducing overall resistance and providing a safer, more reliable path for fault currents—especially in high-resistivity soils where traditional rods or plates are less effective.

Earthing Enhancement Compounds

Marconite®

By adding MARCONITE instead of the sand and aggregate used in a standard concrete mix a highly conductive concrete is formed. Used as a backfill material around the earth electrodes, it provides a conductive medium increasing the surface area of the electrode and ensuring a highly conductive path between the earth electrode and the surrounding ground. Being a concrete it provides a permanent solution.

Bentonite®

BENTONITE is a moisture retaining clay consisting of sodium montmorillonite. By mixing BENTONITE with water the resultant slurry will swell to many times its original dry volume. When used as a backfill material, within a borehole earth system, it will continue to absorb water from the surrounding soil thus helping provide a stable earth resistance. This is also true when the clay is used to surround earth plates and lattice mats. It strongly adheres to the earth electrodes ensuring good electrical conductivity between the electrodes and surrounding ground.

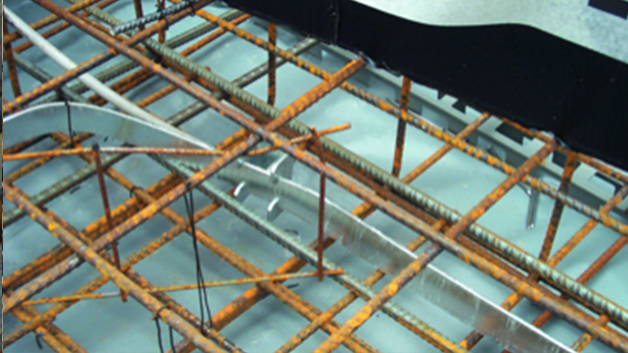

Foundation Earthing: The Ultimate Solution for Safety and Equipotential Bonding

Because foundation earthing uses the building’s concrete-reinforced structure to create a large, low-impedance grounding system. This ensures broad equipotential bonding, minimizes step and touch voltages, and provides long-term stability and corrosion resistance.

Connecting Clamps for Reinforcements

In accordance with DIN 18014 “Earthing systems for buildings – Planning, execution and docu-mentation”, the equipotential bonding conduc-tor/foundation earth electrode must be con-nected to the reinforcement of the foundation slab every 2 metres.

For connecting reinforcing steel mesh or rein-forcements with round and flat conductors.

Arrangement: (II) = parallel (+) = cross

Fixed earthing terminals with flexible connection clamp

for protective equipotential bonding and/or functional equipotential bonding of the down conductor, e.g. to the reinforcement of buildings

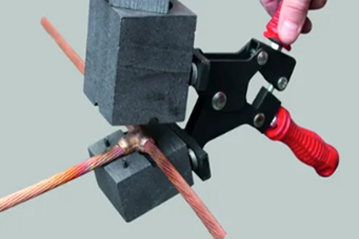

DEHNclip Rebar Clamp

In accordance with DIN 18014 “Earthing systems for buildings – Planning, execution and docu-mentation”, the equipotential bonding conduc-tor/foundation earth electrode must be con-nected to the reinforcement of the foundation slab every 2 metres.

For connecting reinforcing steel mesh or rein-forcements with round and flat conductors.

Arrangement: (II) = parallel (+) = cross

Quick and safe:

The DEHNclip rebar clip for quick connection of the earth electrode to the reinforcement with-out tools. DEHNclip is tested for a lightning cur-rent carrying capability of 50 kA (10/350 µs) in accordance with DIN EN 62561-1.

Connecting Clamps for Fixed Earthing Terminals and Reinforcement

For connecting the reinforcement with clamping piece.

For round conductors or fixed earthing termi-nals with simultaneous fixing in the formwork.

Arrangement:

(II) = parallel

(+) = cross